* Cooling and climatic mattress ticking fabrics make a big difference for an ideal sleep. Turkey has some prestigious brands in the revolutionary business such as award-winning Boyteks, Aydin Tekstil, Comfytex, Kirayteks, etc. Below we studied their cases as well.

* How efficient is Phase Change Materials (PCM) in textiles? PCM plays an important role in modern textiles. The Hohenstein Institute has investigated how effective PCM products are with the help of the WATson Heat Loss Tester.

Innovation has no limits. Who knows what else will come to our surprises… One of the most recent surprises was cool fabric innovation. Used mostly for under and outerwear the innovation is used as bed linens too. How comfortable it would be if you have a cooler fabric under your body in hot seasons! The sleep quality is fundamental of being health, fit, spiritual and physically happy life. It is very important for us to realize the conditions of our sleep as we spend one third of our time sleeping. Based on studies, sleeping in a cooler environment is one of the essential part of a healthy sleep. Stress can increase the affect your health through intensive work pressure and routine life living conditions as well as the overwhelming heat and high humidity. The most effective way of having such a fabric or dress is Phase Change Materials.

Innovation has no limits. Who knows what else will come to our surprises… One of the most recent surprises was cool fabric innovation. Used mostly for under and outerwear the innovation is used as bed linens too. How comfortable it would be if you have a cooler fabric under your body in hot seasons! The sleep quality is fundamental of being health, fit, spiritual and physically happy life. It is very important for us to realize the conditions of our sleep as we spend one third of our time sleeping. Based on studies, sleeping in a cooler environment is one of the essential part of a healthy sleep. Stress can increase the affect your health through intensive work pressure and routine life living conditions as well as the overwhelming heat and high humidity. The most effective way of having such a fabric or dress is Phase Change Materials.

Substances that undergo the process of phase change are also known as phase change materials (PCMs). These materials store, release or absorb heat as they oscillate between solid and liquid form, giving off heat as they change to a solid state and absorbing it as they return to a liquid state.

Some PCMs change phases within a temperature range that is just above and just below human skin temperature. This property now is being used in fabric and foam to store body heat and then release it when needed. PCMs in the form of microcapsules can be incorporated within fibers or foams, or may be coated onto fabrics.

Whether for sports or outdoor wear, personal protective clothing or for bed linen: PCM textiles are becoming increasingly popular. But the greater the number of applications, the greater the demands made on textiles containing PCM. How is the effect they promise perceived by the wearer of such textiles? Until now there has not been any clothing-related physiological method of measuring this. Physical measurements were only able to indicate changes in temperature.

A research project currently underway at the Hohenstein Institute has developed the first measuring method that allows the effect and efficacy of PCM in textiles to be tested without costly wearer trials. This new test method has not only made it simpler to demonstrate the functionality of textiles, but also to offer proof of quality. This research project involved testing PCM-containing products from the market and coating textile samples with varying quantities of PCM.

Does PCM keep what it promises?

Visual inspection allowed differences in PCM modification of the various products to be identified. In the case of coatings it was also possible to detect variations in terms of the quantity and mixing ratio of the substances applied. The encapsulation of PCM in fibers brings about changes in the physical properties of textiles, with some samples showing an improvement in tensile strength. Others however revealed adverse effects, due to poor mixing ratios, uneven spinning masses or porous PCM in the spinning mass.

Investigation of abrasion resistance showed that PCM fibers make twisted yarns rupture more easily in comparison with a reference yarn. Textiles coated with PCM demonstrated low resistance to rubbing and reprocessing. A huge deterioration in the quality and thickness of the coating is observed here. The wash resistance of the PCM finish tested is low, with the PCM material disappearing altogether from many samples after 10 washes.

The heat-insulating properties of PCM products vary widely and depend on the basic construction of the textile. Greater heat insulation was observed for material structures with the use of PCM technology. This is not solely due to the PCM, but first and foremost to the binder systems additionally employed. It was observed here that the heat-insulating property of the tested materials was slightly better if the coated side faced the skin.

Water vapor resistance is generally impaired by the addition of PCM and depends on the structure of the textile.

Wearer trials confirmed by WATson

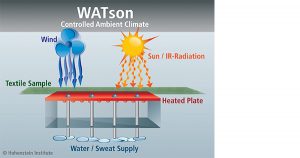

The effect of PCM textiles was demonstrated using the WATson Heat Loss Tester, which is capable of simulating heat build-up and sweating. It was possible to correlate the objective data measured in the investigations using the Heat Loss Tester with the results of wearer trials on PCM textiles. Tests performed on human subjects demonstrated the cooling effects of PCM textiles. In terms of skin temperature they are extremely low. The measurements obtained with the WATson Heat Loss Tester were confirmed by the data from the wearer trials.

WATson – a gain for the textiles industry

These research results make it possible to manufacture new products with a high, verifiable level of functionality and allow them to be tested in terms of function. The WATson Heat Loss Tester supplies objective measured data, which can now be correlated with results from wearer trials. Small and medium-sized enterprises in Germany’s textiles industry can in future call on an objective measuring method for PCM textiles that allows them to supply proof of product quality.

Second WATson increases testing capacity for the textile industry

Modern textiles promise a great deal: some of them are strong performers when it comes to heat and moisture management. A huge amount of scientific research and development work lies behind this functionality. The Hohenstein Institute plays its part as a leading research institution in the field of clothing physiology for the textile industry.

Hohenstein has developed innovative technologies for defining and measuring specific thermophysiological comfort factors. Hohenstein works closely with companies that want to develop or optimize textiles with respect to these factors. The institute is able, on one hand, to work out the best possible product properties and, on the other, to verify marketing claims about cooling effect and moisture management.

Greater security in product development

In order to cope with the high demand from its customers for reliable methods of quantifying cooling performance, Hohenstein can now make use of a second WATson Heat Loss Tester. This has doubled its capacity to measure the actual physical cooling performance of sportswear and functional garments. WATson clearly shows the dynamic interaction between textiles and the human thermoregulation system, in varying climatic conditions and at different rates of sweating. The system analyses even the smallest changes in the cooling sensation that results from evaporation on the surface of the skin and accurately determines the cooling effect that the textile actually delivers by vaporizing perspiration. The WATson technology only requires a textile sample measuring 20 x 25 cm to provide these data for product development, quality assurance and marketing purposes.

Results available within about 10 days

With its additional WATson device, the Hohenstein Institute has doubled its measuring capacity. The properties of all kinds of materials can be investigated flexibly and quickly. The results are supplied within about ten days, so that customer enquiries can be responded to promptly. In addition to carrying out standardized measurement processes, WATson can also be customized to meet specific customer requirements. These two factors – the rapid availability of the results and the customization of the measurements – offer manufacturers a way of measuring and optimizing performance at every stage of textile development. WATson also makes an important contribution to maintaining quality standards at the production control stage.

BOYTEKS’ COOLER TECHNOLOGY

A certain drop in body temperature is to be expected before falling asleep. High ambient temperature makes it difficult for the body to reduce its temperature. It’s difficult for the body to reduce its temperature when the ambient temperature is high, making it difficult to fall asleep. Reduced body temperature makes it easy to fall asleep and improves sleep quality. That’s why sleep technology leader BOYTEKS developed Cooler mattress ticking.

Cooler mattress ticking provides a sense of cool that helps the body stay cool. Cooler maximizes sleep quality by providing a relaxing sleep environment.

Feel refreshed, and fall asleep quicker with the extra comfortable sleep environment provided by Cooler mattress ticking.

COOLNESS, THE AYDIN TEXTILE CASE

As one of the most respectful mattress ticking manufacturers of Turkey, Aydin Textile has been offering real cool fabric for high-end mattress manufacturers. The innovative fabric is called “coolness” at Aydin Textile. This coolness bedding fabric helps the body temperature to decrease though transmitting the heat quickly. Cooling effect is permanent even after washing. It provides a cool sleep environment for better sleep and prevents frequent sleep breaks because of warm weather. It helps to reduce the perspiration during the sleep. It is environmental friendly.

Sleep is a necessary cycle for resting our body, renewing itself and one of the most essential factors that affect our daily life quality. The approach to the coolness fabric is coming from Aydin philosophy; “increasing the life quality”. Over a 24 hour period, our body temperatures naturally peak and decline. Our internal temperature is usually at its highest in the early afternoon and lowest around 5 a.m. When we fall asleep, our bodies naturally cool off. Helping keep your body get to that lower temperature faster can encourage deeper sleep. “Coolness” mattress ticking technology helps you to reduce body temperature to fall a sleep quicker. If your sleep environment is warm, your body will waste energy trying to regulate, and leave you tossing and turning all night. Coolness fabric will support your body to have better sleep even the room temperature is high. It is recommended to use as panel and pillow fabrics. The effect of coolness is permanent and washable. Coolness mattress ticking offers a cool sleeping environment for many years.

COMFYTEX DEVELOPED FREEZE

Turkey’s Comfytex has a fame to offer ideal sleep products made from its revolutionary mattress ticking fabric FREEZE. The sleepers feel the cool comfort all night. FREEZE has high thermal conductivity yarn which can emit the body temperature quickly. It can supply cooling feeling all night which helps having cool, restful and relax sleep. It can also be washed and does not lose cooling efficiency after washing. With Freeze, you can fall asleep more quickly and get a better night’s sleep which decreases your risk for certain metabolic diseases. İf it’s too hot, the body will waste energy trying to regulate, and leave you tossing and turning all night but seeping in cooler environments can help decrease certain types of insomnia. FREEZE helps you to get ideal micro-climatic environment and provides thermal comfort

KIRAYTEKS HAS CLIMATISER®

As one of the leading brands in mattress ticking fabrics in Turkey, Kırayteks utilizes optimum body climate management to produce Climatizer®. Made of conductivity yarn to emit the body temperature, this unique fabric manages to regulate the coolness of the body to offer an ideal sleep. The knitting production line of Kirayteks includes yarn preparation, knitting, dying, finishing and quality control to offer the best alternative for sleep product producers.

#manset

#guncel

SleepTech Magazine Mattress, Accessories, Machinery, Raw Materials

SleepTech Magazine Mattress, Accessories, Machinery, Raw Materials