Promoting health and well being is a key goal of European policy. The EU Framework Directive on Safety and Health at work (89/391/EEC) made a strong commitment to that goal, its stated objective being to ‘encourage improvements in the safety and health of workers’.

The “Sixth European Working Conditions Survey (EWCS)” published by Eurofound (European Foundation for the Improvement of Living and Working Conditions), analyzes the exposure of European workers to physical risks over time, since 2000.

Posture-related (ergonomic) risks is the index that measures exposure to vibrations, tiring positions, lifting people, carrying heavy loads and repetitive movements. These are the most prevalent risks in Europe and include the risks that can play a role in the common workplace complaint, musculoskeletal disorders.

Posture-related (ergonomic) risks is the index that measures exposure to vibrations, tiring positions, lifting people, carrying heavy loads and repetitive movements. These are the most prevalent risks in Europe and include the risks that can play a role in the common workplace complaint, musculoskeletal disorders.

Based on data from the survey, the exposure to repetitive hand and arm movements and tiring and painful positions is highly common, with 62% and 44% of workers, respectively, reporting they are exposed at least a quarter of the time. Likewise, exposure to carrying or moving heavy loads is commonly reported, with 32% of workers exposed at least a quarter of time. These risks are reported in the almost the same level in 2015 than they were in 2005 and 2010.

In terms of occupation, craft workers, plant and machine operators and agricultural workers are the occupations with the highest levels of exposure to posture-related risks.

These general data of the productive sectors are reproduced in a similar way in the industry of furniture manufacturing, in which risks associated with ergonomic conditions are the most relevant.

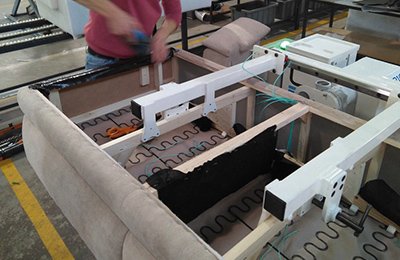

In upholstery, muscular skeletal disorders are the cause of frequent sickness leaves, and involve the most important social and economic cost. These negative consequences have a clear association with the ergonomic conditions of the job – that still involves manual handling and operations with heavy loads – because of the lack of suitable machines or equipment.

The introduction of innovative and specific machinery for upholstery in the market will have a considerable relevance, not only in terms of process optimization, but specially in terms of significantly enhance of worker´s health and well-being.

LIFMEC aim is to bring technology and innovation to upholstery since they believe that the use of their sofa handler would eliminate manual handling and painful or tiring positions for workers. As a result, sickness leaves and the associated costs would be considerably reduced.

LIFMEC aim is to bring technology and innovation to upholstery since they believe that the use of their sofa handler would eliminate manual handling and painful or tiring positions for workers. As a result, sickness leaves and the associated costs would be considerably reduced.

LIFMEC exhibited their innovative product for the upholstery industry: SOFA HANDLER U210 at Interzum 2017 – leading expo about furniture production and interiors design –

The sofa handler U210 is a machine for the assistance of workers in the upholstery stage of the sofa manufacturing process; which can easily lift, position, and turn the sofa. These operations are managed through a handheld industrial remote-control.

The machine allows sofa manufacturers not only to increase process productivity and improve process efficiency, but also significantly enhances worker´s health and well-being.

SleepTech Magazine Mattress, Accessories, Machinery, Raw Materials

SleepTech Magazine Mattress, Accessories, Machinery, Raw Materials